By Billy Aldridge

I know in the past we have discussed how high tech has

been steadily making its way into the bathroom with

| English: Image of HCC MakerBot Cupcake CNC printing of spikey gear and raft in the MakerBot 3D printer. (Photo credit: Wikipedia) |

everything from singing

shower heads to computerized commodes.

Well now it seems that the next wave in

3D printers may soon make it

possible to print everything from knickknacks and plumbing fixtures to an

entire room. While 3D printers have been

a staple of the aerospace and automotive industry for years, they cost hundreds

of thousands of dollars to purchase. This puts them out of the reach of mere

mortals. However, the past couple of

years have seen the costs of these machines drop into the one to two thousand

dollar range and even less as the technology begins to become popular with

hobbyists and small manufacturers. There

are even several startup companies that offer tabletop models for $500 or

less. Even the shipping giant UPS has

gotten into the game (at least in southern California) by offering 3D printing

at their stores.

An article on slate.com states that, “Trialing first in

the San Diego area, with plans to soon expand to other states, UPS stores will

allow customers the opportunity to upload their designs online, have them

printed on the Stratasys uPrint SE Plus printer, and then offer pick-up or have

the results delivered to the client. UPS says it will be able to produce “items

like engineering parts, functional prototypes, acting props, architectural

models, fixtures for cameras, lights and cables.” l

As this technology becomes cheaper, popularity is

surely bound to grow by leaps and bounds, especially when consumers realize how

quickly the units can pay for themselves.

In fact a study just released by Michigan Technological University claims

that the average homeowner could save up to two thousand dollars per year by

owning one of the units. This means that

it would take less than half a year for a 3-D printer to pay for itself. Try getting your plasma TV to do that.

Of course, as with any new technology there is

always a learning curve. Fortunately the

industry has already taken this into consideration. Just as with smartphones, there are a number

of online programming resources that offer 3-D printer designs on the cheap. That’s right, there’s an app for that.

As far as what these babies are capable of

producing, that is dependent upon the size and scope of the

| Sintermask - fabbster - 3D-printer v11 (Photo credit: Creative Tools) |

machine. Just as with early inkjet printers, the

higher the resolution, the higher the price. Even the “toner” used in 3-D

printers can vary. Some of the materials currently used in 3-D printers include

ABS plastic, PLA, nylon, glass filled polyamide, epoxy resin, wax, polymers and

polycarbonate. The biggest drawbacks to

consumer models are processing time (it can take hours or days to print a 3D

model), resolution (hobbyist models sometimes produce finished products that

sport somewhat jagged edges) and size constraints (consumer models can only

produce items that are only about 12” across or less). Of course as the technology continues to

improve the bugs will be worked out, the bells and whistles will become more

refined and the units will decrease in cost.

Anyone remember dot-matrix printers? (For more info and videos goto http://www.3ders.org/3d-printing-basics.html)

Some of the commercial units are built on an

industrial scale, including one in Oakland, California that can construct entire

walls. Below is an excerpt from an

article on TechHive.com:

“Emerging Objects co-founder Ronald Rael explained to TechHive. “We saw a

limitation in what a machine can make because of the medium, and so we wondered

if we could reformulate that media to suit our own architectural agendas to

print big.”

The company's latest star project is an impressive curved

wall that stands about three feet tall. It’s constructed out of centimeter-thin

3D-printed salt tiles that get their strength from their multi-angular

structure: The thinner tiles will allow Emerging Objects to produce many more

parts in a short amount of time than it otherwise could. The wall you see is

just a representation of what Emerging Objects can build in a week with a

couple of machines. Still in the midst of construction, the planned salt wall

will be three times taller when it’s finally complete.”

There is even talk of using 3D printers to

create entire homes, as well as build structures in space. So take it

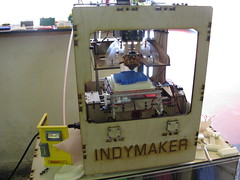

| 3D printer (Photo credit: Indiana Public Media) |

from me that it won’t be long

before consumers can skip the ride to the big box store when they need plumbing

fixtures and other household items. Of

course how long it will be until they can print the plumber to actually install

the fixture is anybody’s guess. But I for

one would never bet against technology.

Billy Aldridge

is one of the Doctors of Plumbology at Aldridge and Sons Plumbing in

Jacksonville, Florida. For even more

helpful hints and how-to videos, visit their site at http://plumbers-jacksonville-fl.com

On demand fabrication via 3D printing is going to be a revolution. I'm excited to see the printers drop in price and allow anyone to own and operate one.

ReplyDeleteCool! I can't wait for the day to come where everyone will be able to to print a McMansion.

ReplyDeleteOur world is changing so fast it could make a trekkies head spin! I can't wait for printed food, oh I forgot that's already real too!

ReplyDeleteSounds like the 1st stage of development of the Star Trek replicators

ReplyDeleteI really loved reading your blog. It was very well authored and easy to understand. Unlike other blogs I have read which are really not that good.Thanks alot!

ReplyDeletehttp://www.alvarezplumbing.com/

The six-member Expedition 53 crew poses for a portrait inside the Japanese Kibo laboratory module with the VICTORY art spacesuit that was hand-painted by cancer patients in Russia and the United States.emergency service

ReplyDelete